EJ257 BUILD - PART II

- supersonicsubawoo

- Mar 23, 2019

- 12 min read

Updated: Aug 26, 2021

I will admit: when I first chained the hoist to the engine and started pumping the hydraulics, I had no idea how this was going to turn out. This was my very first engine build, and on my favorite car, so there was much anxiety behind every parts purchase that I made, and I was quadruple-checking my every step. The most internal work I had ever done with an engine before this point was replacing spark plugs and performing a leak down test, so there were plenty of times where I had to shake or rub the nervousness from my hands. Despite my hesitations, though, it was my determination that kept me in line, and kept me going. I had intensely studied my factory service manual, steadily researched online to no end, locked down on my engineering education at school, purchased and read a number of engine performance books, and was gratefully enriched with the tech support of a very close friend, who was actually very far away - by almost three thousand miles.

(Thanks, Kevin.💚 I still owe you In-N-Out.)

Fortune had it, too, that my father was a mechanical contractor who had built and raced motorcycles when he was my age (pictured right, circa 1977), so he had almost every tool imaginable. He built me a valve spring compressor using a large C-Clamp, which was considerably faster and easier to use than a special tool kit I had purchased for almost $50, and I even used some of his industrial impact sockets nearly the size of my fist to press the bushings into my control arms. My dad made for a second eye when I really needed it, and was my parts runner when I was in a pinch or stuck at work. He also instructed me on the use of different gauges and how to select the right cutters for my valve seats. If not for him, this project would have taken me two years and a potential excess of backtracking, so I'm grateful he was around to support his "little grease monkey." (My parents also let me have their entire garage for this endeavor. Tell me your parents are that cool. :P )

All things aside, I pressed on through this build with one primary goal: success. As much as I intended to build a more powerful and sturdy competition engine, my first aim was to build an engine that simply runs, and one that hopefully runs smooth. Once a running engine was accomplished, my next aim was to drive with that engine, and without any leaks or failures. Once a successful drive was completed, the next aim was to survive a crucial Dyno tune. Then, lastly, the engine would have to withstand the ultimate test: WOT track days.

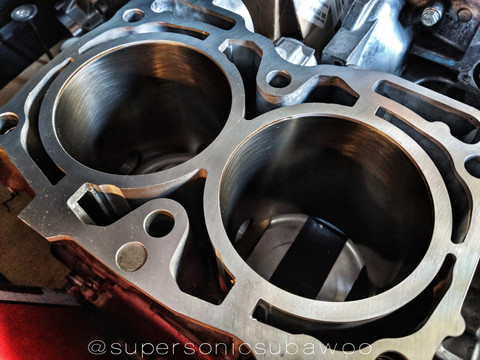

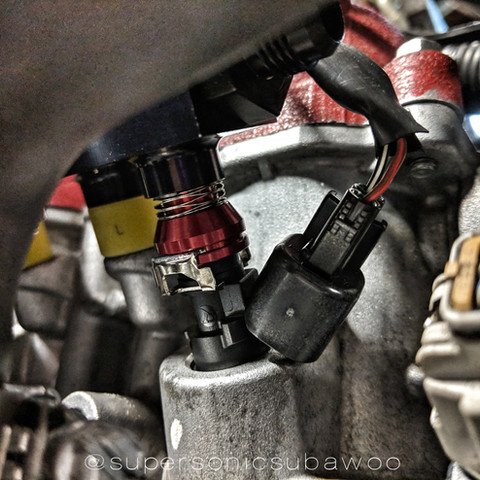

So, now we see how far I got. And to make it more interactive, I will leave this next section to you as sort of a chronological picture book. (There is simply too much information to detail without feeling like it's work to read it, and this will also be a great way of sharing some of my parts choices.) Just click on the pictures to see the details about the capture, then I'll meet you in the next section at the bottom.

THE BUILD

Started: May 19, 2018

REBUILT ENGINE START-UP

Finished: December 19, 2018

After seven full months [on the dot] of intensive care and endless love, Matches was just about ready to start up. And as excited as I was, my nerves were still making the uncertainty known... Using a DMM on the battery proved it was still fully charged, and I did a third or fourth go-around to ensure everything was connected, tight, and in the right place. Before attaching the battery, I proceeded with installing the radiator and setting up a burp funnel on the overflow tank. I began pouring coolant into the funnel, and as I moved to start filling the radiator, coolant started spewing all over the ground from underneath. Realizing the drain plug for the radiator was missing, I turned everything over in the garage looking for it and to no avail. Determined to get this car started "today," I called around to find a replacement, and an auto store almost 20 miles away had one matching plug in stock, so I immediately drove out to retrieve it, walking out with my purchase just as they were closing their doors for the day.

Happy to have found a plug for my radiator on the same day, I was beginning to sense that checkered-flag feeling. I was really this close to crossing the finish line with this build, and was increasingly eager to get it started. I mean, this surely must be the car gods looking out for me, right?!

With the coolant finally in the system, all that was remaining for this process was to start up the engine and get the thermostat to open - a brand new thermostat from a brand I've never tried before. Woohoo! Using a Cobb AccessPort, I reflashed the ECU with a basic OTS map and prepared to prime the oil pump by disconnecting the coilpack plugs before cranking the engine a few times. Nerves returning, I made another go-around to fancy my OCD and to confirm with my gut that we were ready for launch. Excitement was turning to jitters, and as I sat in the driver's seat with a camera running outside to capture Matches's first cranks, I took in a deep breath, turned the key to the on position, and after the gauges were on and ready, I turned the key even further and then...nothing. Absolutely nothing. No crank, no click - nothing.

I was so bummed. Did I plug something in wrong? Did my starter somehow go bad? Was I not careful enough? I got out to overlook everything again, and nothing appeared to be missing or out of place. I started texting Kevin and he was trying to help me solve my dilemma, not realizing it was almost 1am where he was. (Seriously, In-N-Out and cream-filled chocolate discs for life!) Nothing was making any sense to him either, though - everything seemed fine and in place. He finally mentioned checking the starter plugs since everything else was working, so I crawled underneath and noticed there was one last plug to connect - the starter motor signal. Despite how silly it was, the amount of relief that came over me was enough to keep me under the car for a few minutes with my arms and legs sprawled out on the floor. I sighed, plugged in the connector that I had previously secured off to the side of the transmission (which is how I missed it), and returned behind the wheel for another try, getting in about 12 solid cranks twice before leaping out with joy to reconnect the coilpacks.

Now that everything was definitively in working order, it was time for a moment of truth. I stood back to look at everything one more time and briefly relished the fact that I made it this far despite working full time and going to school. I was praying I balanced it right, that all my clearances were within spec for the applications, and that, perhaps, I actually built a race car...

...and, it sounded soooo good!!!

FIRST DRIVE

January 1, 2019

What a way to kick off the new year than to take your first freshly self-built car out for a drive for the first time on the first day of the year. I spent New Year's Eve in the garage installing my new suspension setup and aligning everything best I could. (It was a party. Y'all missed out.) Matches had less than a quarter tank of gas, so as long as I could make it to the gas station and back without problems - a total of five miles - then things were looking up and up! Wheels on, tire pressures set and back on the ground, we were ready to go just before the stroke of midnight. This was literally the best New Year's I've ever had.

Instead of sleeping in on the 1st, I woke up around 6am and started prepping for the big test. This involved an early bird coffee-run with my [very proud] mother via Princess Poppy and staring at Matches from the kitchen table with her in near-disbelief that I could conquer something so huge on my own. "You did this, all by yourself," she said gloatingly, and we both sipped from our cups and beamed in awe of my groundbreaking masterpiece.

After breakfast, I went out to connect my AccessPort and give the engine one more thorough inspection. Feeling good at this point, I started him up, momentarily basked in the voluminous rumble, then set the transmission into first gear. Slowly letting the clutch out, Matches began to roll forward and I barely realized I was holding my breath. Already, the clutch engagement was different, and the exhaust scraped pretty hard toward the bottom of the driveway entering the street so I knew to raise my coilovers back up later. :3 Just for safety's sake, though, I decided to drive around the block, first. I kept the throttle at a minimum and went as far as 3k RPM to begin with, but I gently tapped into it a couple times in 2nd gear to get an initial feel for the traction and power engagements. He was running so beautifully.

Pulling up in front of the house again, I left Matches running on the street in front of the driveway to go grab my wallet (I forgot it) and noticed a substantial leak from underneath the engine as I was walking back down the driveway. I crouched down to find coolant gushing out from the driver side of the engine, and my heart sank. Seeing that the level was still full in the reservoir, though, I quickly grabbed my belongings and booked it 2.5 miles to the gas station.

Starting the gas pump, I stepped back and realized I was never so excited to go get gas before... But, I also noticed that the leakage had stopped, and there wasn't a trail of coolant into the gas station, either, indicating a pressure issue.

Driving back home, Matches was bangin'. Barely half-throttle and he already had some serious get-up, and on an OTS map, no less. Despite being aware of the coolant leak and wondering if I'd have to pull the engine again, I wasn't feeling the least bit dreadful about it. When I got home, I reached underneath with my phone to try and photograph the leak, and found just another silly fix: I forgot to move a water pipe hose clamp up to the hard line, so it was squeezing coolant out the top end of the hose. I laughed - out loud - jacked the front end up, and moved the clamp into place, never to see another coolant leak, and I again remained under the car for a few minutes with my arms and legs sprawled out in relief.

At this point, my confidence was right up there with my determination - and not like the boastful, high-horse type. I was still nervous with the thought of putting Matches on the Dyno, and I still had some doubts about my own build withstanding a track day. But I met, and even exceeded my first two goals. Now, it's just straight business from here.

DYNO

February 9, 2019

The guy I trust most to tune my car had just moved locations, so his Mustang Dyno was in a somewhat portable setup, if you will, but it was more than enough to clear the air pump codes and get some real power out of the build. My heart might have been racing the entire time, but he started Matches and initially ran it straight in third or fourth gear for a few minutes. After he started doing some pulls, the exhaust was spewing some black smoke, then flames, then no smoke at all. About three hours later, I had a 360-whp tuned car that survived the Dyno, and he told me I "built a better engine than seven or eight shops in Orange County" before informing me that my Subaru is officially his favorite Subaru. ♡

FIRST TRACK DAY

March 20, 2019

The day finally came that I was to put my build to the ultimate test. I had now accomplished three of four goals, and while the Dyno tune fell short of the 400whp I built it for, I got the most out of pump gas to see how - or if - the engine holds together during a track day.

My parents' Nissan Pathfinder had a class-III tow hitch, so my dad offered to tow us to the track. When I first saw a U-Haul trailer in person, I wasn't feeling too sure about Matches clearing the ramps so my dad and I debated getting some two-by-fours to assist. After we brought the trailer to the house, though, my dad took some measurements and determined the car would make it up just fine. (He's been towing big, heavy stuff on trailers and rigging for a long time.) Aside from the bumper popping up and over the forward bump-stop and knocking off the front lower wheel guards, Matches made it up without any scraping, and I was well on my way to track-testing.

It was determined that the drive to the track would take over 2 hours with the trailer, so the plan was to be on the road by 4:30am the next morning. When I got up at 4am, I saw a missed text message from my brother asking when we were all leaving for the track. He lived in San Francisco and was due to be in town soon for a break from work, and we thought we would be seeing him the next day so I just text him back saying "4:30" and proceeded to get ready. He immediately text back, though, asking if I was at our parents' house, and just a few minutes after confirming, I heard a bunch of commotion in the front room, as though my parents were freaking out about something. Walking into the living room, I looked toward my mom opening the front door and my brother entered the house. He had driven down the night before as a surprise to go to the track with us, and to see my build in action. It was a really cool big-brother thing to do, and now my track day had full family support. ♡

I always made the tradition of stopping at Starbucks on Rancho Vista off the 14 en route to Willow Springs Raceway, so we all pulled off there for coffee and a bite to eat. We were discussing plans for the day and I was having to admit that the amount of time I would be at the track was dependent on whether my engine survived the first session. While it was just a scenario to consider, the thought made me cringe, but my dad even said, "It's gonna do fine, you did a great job." As much as I was hoping for a good outcome, though, the 30-degree weather only amplified my chills.

Arriving at the track was a milestone in itself. Pulling into the pits and running over to the sidewall of the track, I was home-sweet-home after a few long years of hiatus. It had been a while, and I already knew I wouldn't be driving with full aptitude for the day, but I was ready and willing to go full-throttle and get the most out of Matches that I was physically able to at this point. With all this new suspension and tire setup, too, one could say I arrived with an entirely new car.

I first threw out my back crawling into the car from the rear hatch to get it off the trailer (I actually heard the internal "thunk" of my vertebrae twisting), not realizing until the end of the day that the trailer's axle covers on each side actually folded down, so I was in a lot of pain for being a derp. It wasn't going to stop me, though, so I took a wad of microfiber towels and rolled them up thick to position them behind my back on the seat throughout the day.

Checking my fuel gauge, there was just shy of half a tank to start, so I drove over and filled up with 100-octane racing fuel.Returning to my pit area, I lowered the tire pressures to my previous standard, not sure how much different from the R888s that the R888Rs would really be, but I finally entered the track a couple minutes late into my run group.

My first lap around was very hesitant, as though I was just cruising through a canyon road for the first six turns. I had little desire to brake hard or floor it coming out of the turns, but entering the back straight, I was finally about to redline it for the first time. I kept it in fifth gear and reached upwards of 110mph into turns 7 and 8, and slowed to under 90 in turn 9 (which was actually quite slow for me in contrast to previous track days). Downshifting to fourth gear and swinging wide out into the front straight, we went pedal to the metal and reached just over 120 mph before braking into turn 1 again. From then on, I was inching faster and faster throughout the session, later making it back to the pits with my first successful track run.

And that first session was it. That was my proof. Even though I continued driving and redlining another three sessions before calling it quits due to heavy rain, I made it through an entire 30-minute session, then an entire day with zero mechanical issues, zero leaks, and zero failures.

I build race car!!!

It's onwards an upwards from here, regardless of what happens. There are plans I have drawn up that still need applied which will set Matches well over the 400whp mark, as well as suspension and brake upgrades to keep him grounded for time trials. But I began this venture by setting four goals in place to reach one sole objective, all of which were met triumphantly, and humbly - and timely! There are various degrees in defining success, but (fingers crossed) I think it's safe to say that Matches and I just might have reached the stars.

...Subaru stars, that is. :P

Here's the start line:

Subscribe below to join me in my pursuit.

Until next time…

Maintenance regularly; drive often.

All photos/videos by me, unless otherwise noted.

Life’s obstacles are more entertaining with a sports car.™

コメント